The World Manufacturing Report 2021 indicates the path to a Digitally-Enabled Circular Manufacturing

The 2021 World Manufacturing Report: Digitally Enabled Circular Manufacturing analysed the drivers, opportunities, and challenges in the transition to the circular economy. In particular, it focuses on the potential of digital technologies to achieve circular manufacturing and identifies policy and other enablers to build circular value chains. The Report also outlines key recommendations, developed with a global group of experts, addressed to companies, policymakers, educators, and the society at large to promote digitally-enabled circular manufacturing. More than 50 contributors and experts from over 30 countries collaborated to develop the Report.

Young Manufacturing Leaders also contributed to the Report by submitting case studies the showcase how companies employ digital technologies to support objectives such as achieving resource efficiency, waste reduction, and lowering emissions in their production and value chains.

Get to know the winners of the YML Contest for the 2021 WM Report

The 2021 WM Report defines Circular Economy as an opportunity to transform manufacturing. The circular economy emphasises the design of products to ensure that their components can be recovered at a later stage and that they can be recycled or remanufactured for use in similar or other products. Manufacturers can also leverage new or improved business models that are based on the circular economy, in particular, product as a service models (PaaS) which bundles products with subscription services or service contracts.

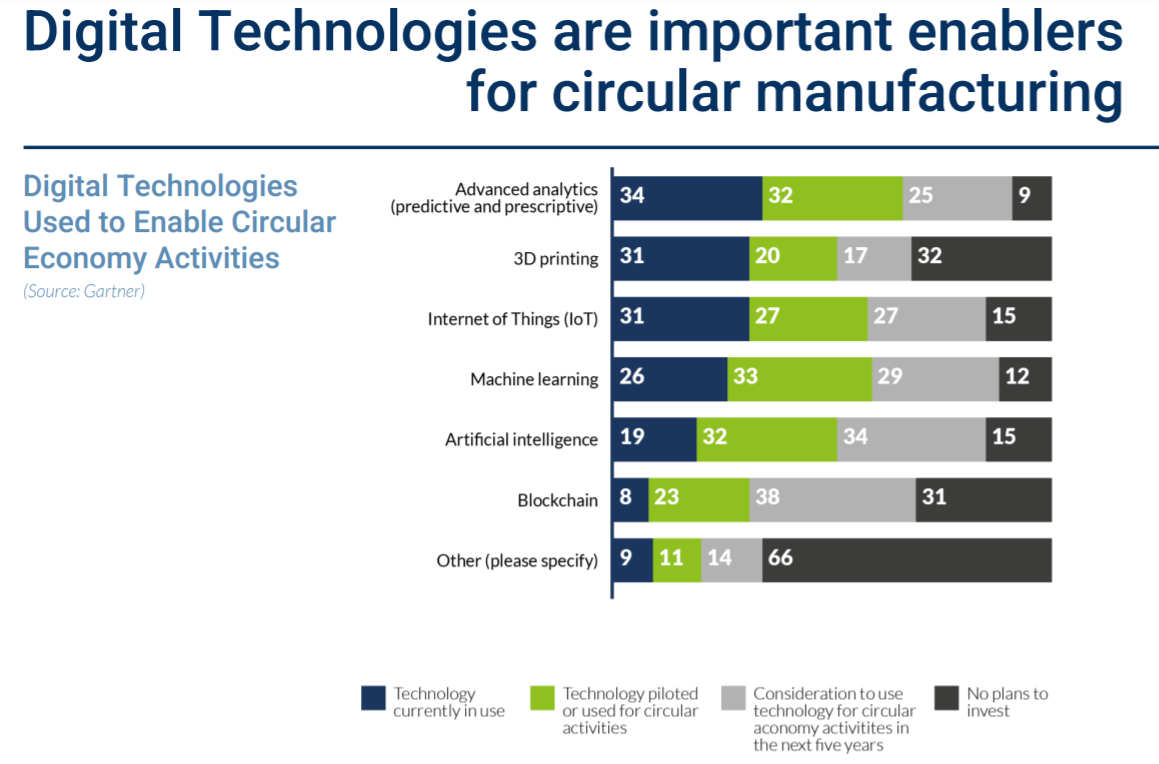

As identified in the WM Report, Digital technologies are the main enablers for circular manufacturing. In fact, in order to fully take advantage of the opportunities of the circular economy, companies must exploit digital technologies to support them on the path towards environmental sustainability. The Report for example outlines how 3D computer-aided design can be utilised in new product development to design products that can be easily recovered or reconfigured at their end of life. In the same way, Artificial Intelligence (AI) and Machine Learning (ML) can allow manufacturers to analyse large amounts of data to make production more sustainable or analyse how consumers use their products. The traceability of materials and products throughout the entire value chain can also be improved by sensors enabled by Internet of Things.

The positive impact of technologies in the transition to the circular economy can only be possible if we address an equally bigger problem – the digital divide in companies. The slow pace of digitalisation especially in SMEs and in developing countries remains a barrier in the transition to circular manufacturing. Accelerating the digital transition will enable companies to overcome the challenges and reap the opportunities afforded by the circular economy.

Digital technologies are only one side of the flip coin. For instance, the successful transition to circular manufacturing requires support from all manufacturing stakeholders. Each individual has a stake in the circular economy and has a role to play. First, companies must understand that the transition to the circular economy is not optional but a must. They should acknowledge that resources are finite and adopt a broader view of the product lifecycle. It is equally important to educate citizens on the importance of sustainable production and consumption so they can make environmentally conscious decisions. Consumers for their part should make informed decisions when purchasing new products and be mindful of how these products are used and eventually disposed of. Governments should promote policies that promote the use of technology in the transition to circular manufacturing. Policies should jointly address digital and green transformation in economies as they are complementary.

Data sharing among different actors should also be encouraged. For example, the creation of shared data spaces provides the infrastructure and facilitates the sharing of data among different participants in a trustworthy way.

It is important to ensure that workers’ skills and competencies are up to date, as they will have to deal with more complex circular value chains and business models that are service-driven. New kinds of skills such as dealing with increased complexity will be required from workers, as well as skills that are needed in new green occupations. Finally, it is important to perform a holistic and realistic assessment of technology impact. The use of digital technologies should support the circular transition and not contribute to waste generation and the climate crisis.

2021 WM Report Ten Key Recommendations

- Promote A Circular Company Mindset that Embraces the Opportunities of the Circular Economy and the Enabling Role of Digital Technologies

- Drive Circularity through Consumer Responsibility, Proactivity, and Conscious Decision-Making

- Enable Cooperation among Relevant Stakeholders in Building Circular Value Chains

- Promote Business Models and Value Propositions that Embrace Circularity

- Implement Policies Globally that Recognise Digital Technologies as the Main Enabler for Circular Manufacturing

- Promote Economic Measures that Drive the Transition to the Circular Economy and adoption of Enabling Technologies

- Train The Workforce for Digitally Enabled Circular Manufacturing

- Leverage on Data to Support the Circular Transition in the Manufacturing Sector

- Empower SMEs In their transition to Circular Manufacturing

- Address the Possible Negative Environmental Impact of Digital Technologies